AI-Powered Production Planning & Scheduling (PPS) for Smart Manufacturing

In today's competitive market, smart manufacturing and AI-driven Operations Scheduling your factories essential for companies aiming to boost productivity, improve asset utilization, and deliver high-quality products on time. Our Production Planning and Scheduling (PPS) software transforms complex factory operations into optimized, intelligent systems that drive measurable and meaningful short-term profitability.

Key Results For Smart Production Scheduling

Optimized Equipment Loading:

Ensure that all production equipment is used to its maximum potential through real-time capacity balancing and intelligent workload distribution.

Intelligent Sequencing:

Automate production and efficiency by positioning operations based on material availability and production priorities.

Key Benefits of AI-Powered PPS For Manufacturing

On-Time, In-Full (OTIF) Delivery:

All delivery commitments to customers using AI-powered delivery compliance reports and proactive issue identification.

Reduced Work-in-Progress (WIP) and Finished Goods (FG) Inventory:

Achieve a lean manufacturing approach with minimized WIP, optimizing storage costs and improving cash flow.

Comprehensive Production Planning Capabilities

Advanced Scheduling Features

Order Promise Engine

With real-time data, our Order Promise Engine allows you to meet customer capacity requirements and provide accurate delivery promises. Using AI-based predictive analytics eliminates data on production timelines and supply availability.

Simulation and What-If Scenarios

Run multiple scenarios to plan the impact on production schedules. This feature allows you to make informed operations by evaluating the complete ramifications on capacity, resource allocation.

Order Priority Management

An advanced sorting system that allows priority-based queuing based on customer order criteria such as profitability or priority orders are delivered on-time regardless of other demands.

AI-Driven Delivery Forecasting

Aur delivery forecasting leverages advanced AI to generate accurate predictions by analyzing order patterns, considering capacity constraints, historical executing, and production schedules and capacities across plants.

Make-to-Order (MTO) and Make-to-Stock (MTS) Flexibility

Our systems adeptly handle both Make-to-Order and Make-to-Stock manufacturing, ensuring optimal production control and automatically generate orders based on stock levels and demand forecasts. This becomes efficient planning among both production strategies to maximize production output.

Constraint Management

Identify constraints efficiently and intelligently balance constraints such as workforce and material and Equipment optimization and materials for optimal line efficiency.

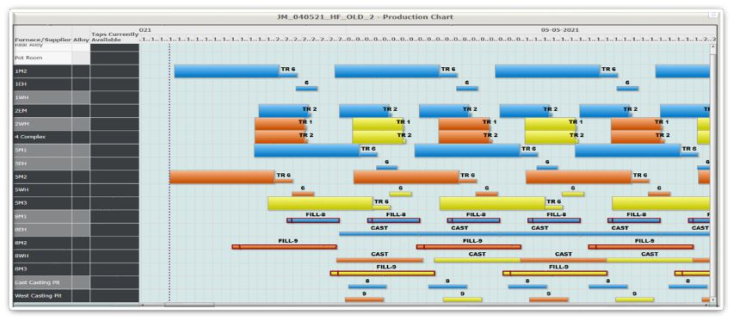

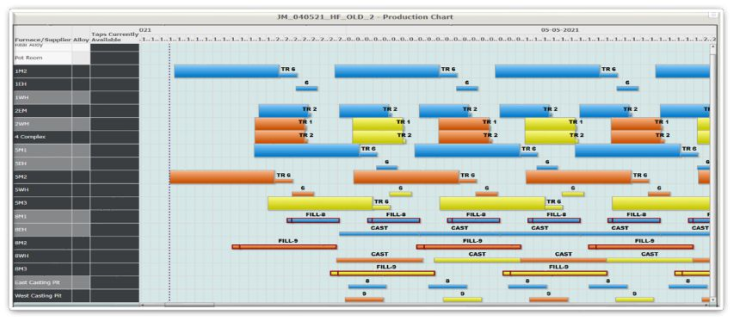

Campaign Planning and Execution

Our advanced scheduling helps campaigns using detailed batch processing plans, minimizing equipment downtime, and increasing throughput.

Integrated End-to-End Scheduling

Our end-to-end scheduling delivers integrated all stages of production from procurement to delivery ensuring that multi-location operations are synchronized based on material availability.

Multi-Level Bill of Materials (BOM) Optimization

The advanced multi-level BOM sequencing to ensure continuous flow from level RM/intermediate and production priorities, optimizing the sequencing of orders and line assembly sequencing based on capacity and material resources streamline your production cycle.

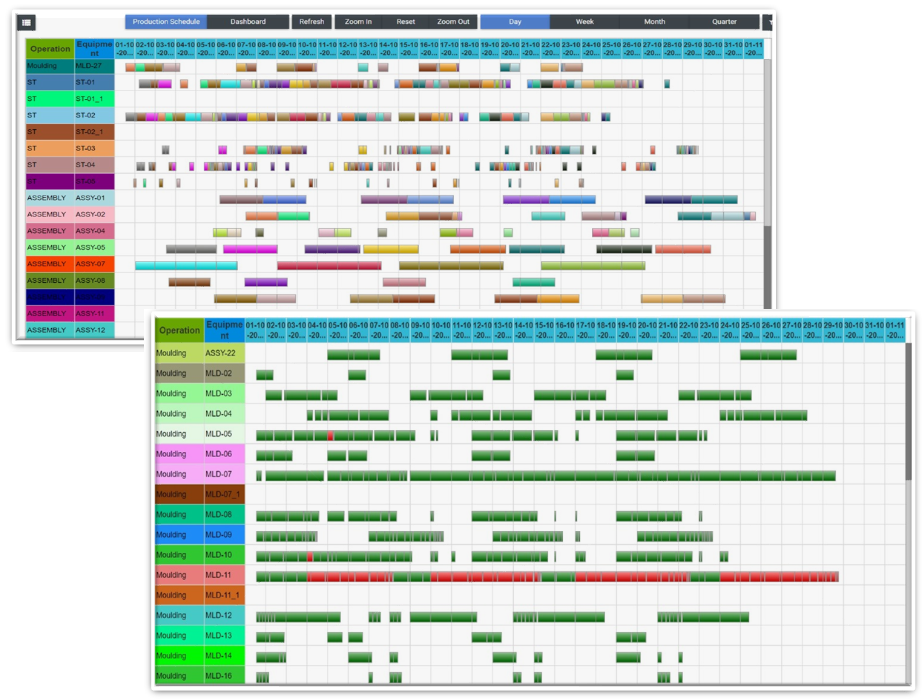

Multi-Factory Scheduling

The businesses operating in multi-factory environments, our systems allow you to manage production across different plants efficiently. It helps balance loads between factories for producing finished goods in-house and outsourcing intermediates or raw materials to vendor locations.

Advanced Manufacturing Capabilities

Comprehensive Schedule

Optimizes end-to-end Production schedule across all processes and resources until user plans.

Production Sequencing

Optimizes sequence for all equipment to maximize productivity and ensure delivery. Best sell-through optimization based on material availability.

Optimal Capacity Utilization

Distributes load on equipment optimally based on capacity and constraints. Distributes material across equipment and optimize capacity and equipment sharing for lines.

Multiple Factory Schedule

Print with multi-factory scenarios where there are multiple sites responsible for producing finished goods to work materials.

Production Sequencing

Optimizes sequence for all equipment to maximize productivity and ensure delivery. Best cell optimization based on material availability.

Optimal Capacity Utilization

Distributes load on equipment optimally based on lines balanced and constraints. Distributes load on capacity and equipment for lines.

Multiple Factory Schedule

Print with multi-factory scenarios where sub-assemblies are responsible for producing intermediate to raw materials.

Transform Your Production Planning Today

Experience the power of AI-driven production planning and scheduling for your manufacturing operations.

Request a Demo